Retaining Wall Construction Services Professional Retaining Wall Design & Build

Fundamentals of Retaining Wall Construction

Retaining wall construction refers to the process of building structures that hold back soil or earth when there is a change in elevation or slope. These walls allow you to create level terraces, prevent erosion, manage drainage, and reclaim usable land from sloped terrain. Without a properly engineered retaining wall, soil pressure, water buildup, and slope failure may damage property or lead to collapse.

A full retaining wall service typically includes site analysis, geotechnical evaluation (soil type, water table, bearing capacity), design engineering, selection of retaining system (gravity wall, reinforced, geocell, gabion, soil nail, etc.), drainage planning, structural reinforcement (geogrids, rebar, anchors), and final wall construction. Quality services also include warranties, maintenance plans, and inspections over time.

Why You Should Invest in Professional Retaining Wall Construction Services

Long-Term Structural Stability & Safety

A properly constructed retaining wall resists lateral earth pressures, water loads, and potential surcharge loads (vehicles, structures) over time. Professionally engineered walls ensure correct footing, reinforcement, and drainage, reducing the risk of tilting, sliding, or collapsing.

When a wall fails, repair is costly and disruptive. Engaging professionals from the start ensures safety, longevity, and structural integrity.

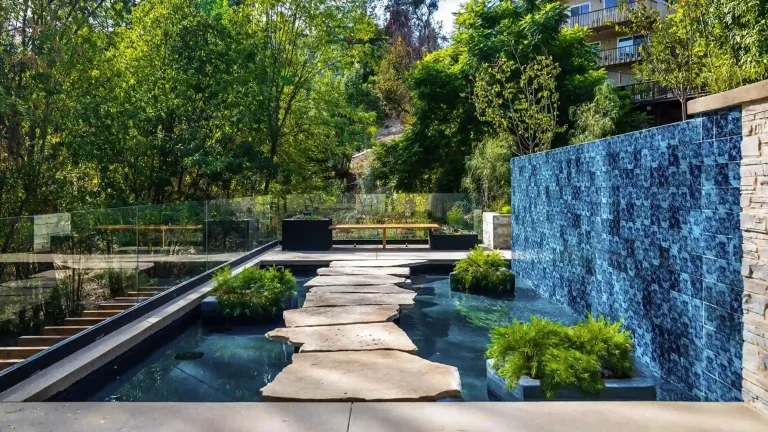

Increased Usable & Aesthetic Land

Sloped or uneven terrain often wastes space or limits landscaping options. Retaining walls allow you to flatten lawns, expand patios, build terraces, or create raised garden beds. This reclaiming of usable land improves both form and function.

Additionally, retaining walls can be shaped, textured, and faced with attractive materials (stone, block, gabion) to become aesthetic features, not just utilitarian structures.

Erosion Control & Drainage Management

Water accumulation behind a retaining wall can generate hydrostatic pressure, increasing failure risk. Quality construction always includes drainage layers: weep holes, perforated pipes, gravel backfill, filter fabrics, and drainage boards. This water management protects both the wall and the adjacent soils.

Especially in heavy rainfall regions, proper drainage ensures the wall doesn’t suffer from freeze-thaw damage or soil saturation failure.

Adds Property Value & Functional Enhancement

A well-executed retaining wall is an investment. It improves curb appeal, usable acreage, and landscaping potential features attractive to buyers. In many cases, such structural features raise property value and aesthetic prestige.

Moreover, walls can be integrated with steps, seating ledges, lighting, and planters, making them multifunctional elements in an outdoor space.

Maintenance Efficiency & Durability

When using high-quality materials and following best construction practices, retaining walls require minimal ongoing maintenance. Proper drainage, reinforced systems, and durable facing reduce repairs over decades. Over time, the minimal maintenance cost justifies the upfront investment.

Types of Retaining Wall Systems & Technologies

Gravity Retaining Walls

A gravity wall resists soil pressure using its own mass. Materials such as concrete, large stones, or heavy blocks are thick and wide to counteract lateral forces. Gravity walls are suitable for shorter heights (typically up to 2–3 meters, depending on soil and load).

These walls are simpler but require substantial mass or footing width to ensure stability. For low-height landscaping walls or garden terraces, gravity walls are cost-effective and reliable.

Reinforced / Mechanically Stabilized Earth (MSE) Walls

MSE or geosynthetically reinforced walls integrate geogrids or geotextile reinforcement into the backfill soil to improve strength and stability. The facing may be modular blocks or segmental units. This technique allows higher walls using less footing depth.

Because the soil and reinforcement become a structural composite, MSE walls adapt to settlement and are flexible, making them ideal for tall walls or heavy loading.

Gabion Walls

Gabion walls use metal wire baskets (gabions) filled with rock or aggregate. These open-draining walls are effective for erosion control, slope stabilization, and retaining soil.

Gabions are ideal where drainage is critical and aesthetic texture is desired. They are relatively forgiving of minor settlement and do not require mortar or deep footings in many cases.

Soil Nail Walls

Soil nailing involves inserting reinforcing bars (nails) into soil slopes, then applying shotcrete or facing. It’s often used for slope stabilization or retaining wall retrofit.

This method works especially well for existing slopes or excavation cut faces where constructing a full retaining wall is impractical.

Embedded / Cantilever Walls & Slurry Walls

For deep excavations or high loads, walls may be embedded or cantilevered using reinforced concrete footings. Slurry walls are used in conditions with high groundwater or tight spaces, constructed via trenching and backfilled with slurry.

These systems are typically engineered solutions in infrastructure projects rather than small landscaping walls.

Innovations & Technology in Retaining Wall Construction

Drone-based Quality Control & GPR Inspection

Modern projects use drone-mounted ground-penetrating radar (GPR) to non-destructively inspect wall depths and internal structure during and after construction. This helps verify that the wall conforms to design tolerances without costly excavation.

Such technology improves quality assurance, allows early detection of anomalies, and reduces rework risks.

Use of Smart Sensors & Monitoring

Smart sensors embedded in walls can monitor strain, movement, or moisture levels over time. This real-time feedback helps catch structural issues early.

Wireless sensor networks in retaining walls are evolving to increase safety and predictive maintenance.

Advanced Reinforcement & Geogrid Materials

New geogrids, geostrips, and high-strength synthetic materials enhance pulling strength, linkage, and durability. These reinforcements allow a more efficient, lighter design of MSE walls.

Also, modular block systems (such as VERSA-LOK) use pinned interlocks for stability with reduced protrusions.

Computer-Aided Design & Modeling

Engineers now use advanced software and finite element modeling to simulate lateral earth pressure, settlement, drainage behavior, and wall performance. Designs can be iteratively refined before construction begins, minimizing surprises in the field.

Machine learning and optimization algorithms are also emerging in optimizing wall geometry, reinforcement layout, and material use under multiple constraints (cost, weight, seismic loads).

Remote Deformation Monitoring (Laser Scanning)

Terrestrial laser scanning measures lateral deformations of retaining walls in real time. These high-resolution scans detect movement or bulging, enabling preventive maintenance.

Such scanning helps ensure long-term wall integrity and can inform repairs before failures.

Real-World Product Examples for Retaining Wall Construction

Here are five real products or systems used in retaining wall construction. Each is detailed with features, benefits, use cases, and where to buy (affiliate style).

1. Adbri Masonry 400 × 190 × 200 mm Charcoal Versasmooth Standard Block

This is a modular concrete block used in retaining wall systems, known for its smooth face and reliable dimensions. It offers consistency in stacking and facing.

Details & Benefits:

-

Smooth finish gives clean, modern aesthetic

-

Standard size improves structural predictability

-

Concrete block material resists rot, pests, and fire

-

Easy to stack with mortar or dry-stacked methods

Use Case / Problem Solved:

When creating low garden walls or terraces where aesthetics matter but strength is essential, these blocks allow precise alignment and face appearance while retaining soil.

How & Where to Buy:

Available via masonry suppliers or block manufacturers.

2. Brighton Masonry Eziwall Lite Retaining Wall Block

Eziwall Lite is a lightweight, interlocking block designed for gravity or reinforced retaining walls. Its integrally colored face reduces the need for surface finishing.

Details & Benefits:

-

Lighter weight means easier handling and reduced labor

-

Interlocking design stabilizes the wall face

-

Color throughout the block reduces visible wear

-

Suitable for planter walls, seating walls, and landscape terraces

Use Case / Problem Solved:

When constructing walls where limited loading is expected, and you want to reduce labor and time, these blocks simplify construction while giving clean, attractive face results.

How & Where to Buy:

Offered by Brighton Masonry distributors and online masonry suppliers.

3. HDPE Geocell Plastic Landscape Geocell Retaining Wall

HDPE (High-Density Polyethylene) geocell is a honeycomb-like cellular confinement product used to reinforce soil in retaining or slope applications.

Details & Benefits:

-

Flexible grid confines infill (soil, aggregate), improving shear strength

-

Light, rollable, easy to install on slopes

-

Suitable for erosion control, slope retention, and green wall facings

-

Works well with vegetated or planting finish surfaces

Use Case / Problem Solved:

When constructing a steep slope wall where traditional block might be heavy or difficult, geocell systems provide structural support while enabling green facings or planted surfaces.

How & Where to Buy:

Found on engineering supply sites or geosynthetics vendors.

4. Richell Deep Type Earth Retaining Stone Masonry Type 45 Dark

This is a deep stone masonry block often used in decorative retaining wall facings. It gives texture and a natural stone aesthetic.

Details & Benefits:

-

Deep profile provides more strength and depth

-

Dark stone offers a classic, high-end finish

-

Combines structural support with architectural appeal

-

Suitable for both internal masonry walls and external retaining systems

Use Case / Problem Solved:

For clients wanting a natural stone facade with structural integrity, these masonry blocks allow the wall to serve both engineering and visual roles.

How & Where to Buy:

Available via specialty masonry and stone suppliers.

5. Retaining Wall Type L 160 × 80 × 80 Block

This is an L-shaped precast concrete block used in retaining wall corners or as modular retaining elements.

Details & Benefits: The

-

L shape provides structural resistance at corners or vertical transitions

-

Solid concrete ensures strength and durability

-

Modular size allows systematic layout planning

-

Useful where wall geometry changes direction or slope

Use Case / Problem Solved:

In designs where walls turn corners or steps, L-shaped blocks simplify alignment and strengthen transitions against soil pressure changes.

How & Where to Buy:

Available through precast concrete block suppliers.

How Technology Enhances Retaining Wall Benefits

-

Geocell & Geogrid Integration: Reinforcement materials make walls more flexible, stronger, and capable of withstanding settlement and seismic forces.

-

Smart Monitoring: Sensors and drones allow real-time quality checks and long-term structural monitoring to catch early shifts or defects.

-

Advanced Block Systems: Pinned interlocking block systems (e.g., VERSA-LOK) reduce weak joints and simplify construction.

-

Modeling & Optimization: CAD, FEA, and optimization algorithms reduce overdesign, optimize material usage, and ensure safety margins under varied loading.

These advances improve safety, reduce repair costs, and allow more ambitious landscape designs.

Use Cases & Problems Solved by Retaining Wall Construction

Creating Terraced Gardens on Steep Slopes

In hilly or mountainous terrain, simple planting is impossible. Retaining walls create terraces, enabling gardening, pathways, and flat usable zones. The wall holds back soil and supports level beds.

Preventing Soil Erosion on Sloping Properties

Heavy rainfall can wash away topsoil, damage foundations, or trigger landslides. A retaining wall with proper drainage prevents soil migration and retains landscape integrity.

Driveway or Road Edge Retention

Where driveways or roads run near slopes, retaining walls support adjacent soils and prevent collapse or undercutting, especially when fill or cut banks are involved.

Foundation and Basement Retention

For houses built into slopes, walls against excavation faces or basements act as retaining structures. These walls must resist high pressures and often include waterproofing and drainage systems.

Supporting Pools, Patios & Hardscapes

When building patios or pools at higher grades, retaining walls support hardscape and ensure they remain stable over time. They prevent shifting or cracking due to soil movement.

How to Hire or Commission a Retaining Wall Construction

-

Site Assessment & Soil Testing

Engage geotechnical engineers to analyze soil type, bearing capacity, water table, slope angle, and load conditions. -

Design & Engineering

A structural engineer designs wall types, reinforcement, footing, and drainage, abiding by local codes and safety margins. -

Obtain Permits & Approvals

Retaining wall projects often require municipal approvals, especially for walls above certain heights. -

Select Materials & Suppliers

Choose high-quality block systems, geogrids, drainage pipes, filter fabrics, etc. -

Hire an Experienced Contractor

Ensure the contractor has a track record in retaining wall construction and understands soil, drainage, and structural principles. -

Quality Control & Inspection

Use technologies (drone GPR, sensors) to verify wall depth, integrity, and conformance. -

Maintenance & Monitoring Plan

Schedule periodic inspections for settlement, drainage clogging, vegetation roots, and structural movement.

Frequently Asked Questions

Q1: How tall can a retaining wall be built safely?

A1: It depends on wall type, design, reinforcement, soil, and drainage. Simple gravity walls are often limited to 2–3 m. Reinforced systems (MSE, geogrid) can reach much greater heights with engineering design.

Q2: What is the role of drainage behind retaining walls?

A2: Drainage prevents water buildup and hydrostatic pressure, which can cause failure. Proper drainage (weep holes, perforated pipe, gravel, filter cloth) is essential for long-life performance.

Q3: Can retaining walls be DIY projects?

A3: For small, low-height walls with simple blocks, a skilled DIYer might manage. But for heights, complex soils, or when reinforcement is needed, professional design and installation are strongly recommended.